Welding Rotators: Basics & Benefits

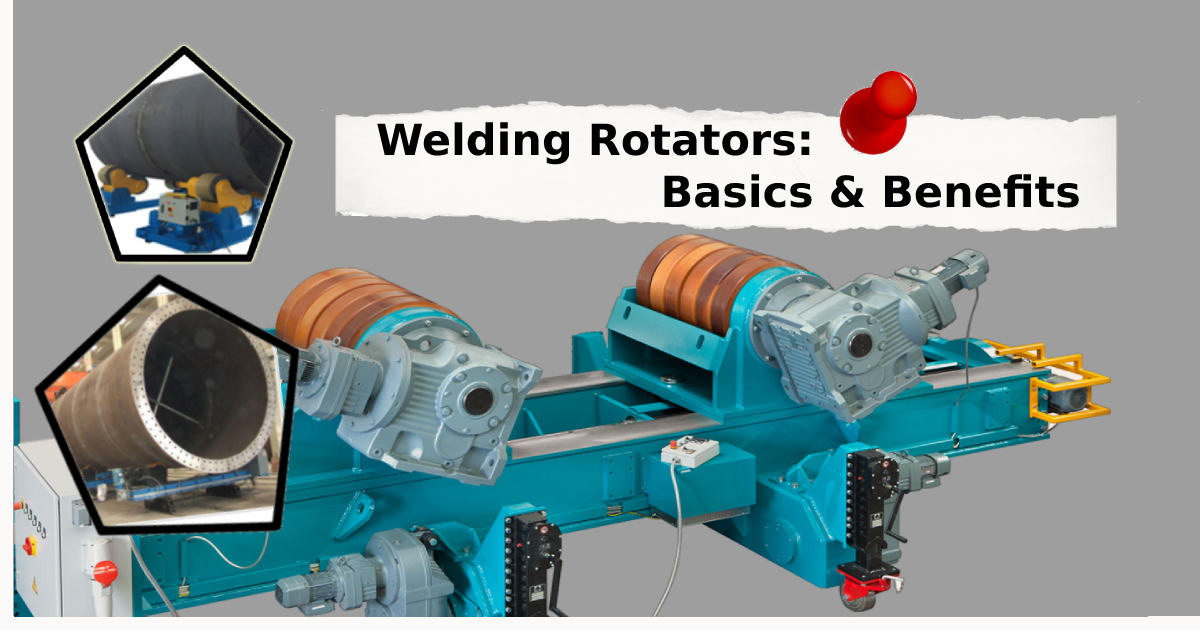

As we all know that, today the welding rotator plays an important role in the welding process. A welding rotator is a type of equipment you can use to make your welding processes easier. Welding Rotators are used to rotate and manipulate Tanks, Pipes, and any other type of cylindrical object. These “Welding Rotator/Welding Rollers” units provide a wide array of component manipulation and precise rotation speed adjustments as needed for any Tank or Pipe Rotation purposes. This reduces the preparation time and allows the operator to manipulate workpieces to the optimal position.

Read on the basics and benefits of Stud Welding machine

Types of Tank Rotators

- Conventional Tank Rotators

- Self-aligned Tank Rotators

Conventional Tank Rotators

Conventional Welding Rotators are a type of welding rotator manufactured by using optimum quality steel material and cutting-edge technology. To ensure its operational safety and performance, the rotator machines are strictly checked on various quality parameters under the supervision of quality testing engineers. Offered Conventional Tank Rotator is highly acclaimed for the below-mentioned characteristics:

- Easy & safe operations

- Prolonged working life

- Resistance against corrosion & abrasion

- Ultraviolet stability

Self-aligned Tank Rotators

Self-aligning tank rotator feature of the wheel brackets allows the wheels to automatically align themselves when a pipe or vessel is loaded onto the sections, irrespective of ovality, to accommodate any diameter within their range.

With a conventional rotator, the wheel brackets have to be adjusted manually across the frames to accommodate the varying diameters within their range.

Bode Patented Self-Aligning Rotators

- Instantly self-aligning to the workpiece.

- Robust all-steel welded construction.

- Clutches are incorporated in top rollers of the Drive Section to prevent damage to the transmission when loading.

- Variable speed rotation through AC inverter control.

- Tachometer speed indicator (optional).

- Anti-Creep fitted to ldler Section (optional).

As is to be expected of Bode machinery, all Traversing Self-Aligning Rotators are built to the highest standards with quality materials and components:

- Robust, all-steel construction

- Inverter-controlled traversing and rotation at welding speeds.

- All rollers of the Drive Section are positively driven.

- Clutches are incorporated in top rollers of the Drive Section to prevent damage to transmission during loading.

- On unloading easy-pivot roller brackets operate in reverse, moving to their resting position, ready to take the next piece.

- Idler Section can incorporate a manual or electric anti-creep feature to restrict vessel ‘creep’ to +/– 1 mm

Welding Rotator Applications

Most common applications you can have of it include the welding of:

- Storage Tanks

- Water Tanks

- Shipyards and Ship Components

- Pressure Vessels

Benefits and Advantages of Welding Rotators

The benefits and advantages of using welding rotators are endless. Some of the most common benefits and advantages are;

- Increased Productivity

One of the primary benefits of using welding rotators is that you get increased productivity. It is because you wouldn’t be meddling with the workpiece, your welders can stay in one position and perform the weld. This can actually be efficient and effective in promoting your overall productivity.

- Safe

With a welding rotator, the workers don’t need to worry or think about manually handling workpieces; you can mount them onto the welding rotator so they’ll move, rotate, and spin automatically.

- Quality Welds

By automating the rotation of the workpieces, you can be sure that the high-quality welds, accurate, and more precise.100% match the plan and the results you are expecting to get.

Disadvantages of Using Welding Rotator

- Only Effective in Materials With Good Weldability

- Required experience

Learn the complete review of Kistler Programmable pipe cutting machine

If you’re looking for a quality Tank or Pipe Welding Rotators rental in UAE, then contact YES Automation. The best metal fabrication rental company that supplies machinery equipment all around the globe.